The Complete Guide to Fadal NSK Ballscrew Assemblies (BLS-0137N-ASS): Precision, Installation & Maintenance

15May

Introduction

In CNC machining, ballscrew accuracy directly impacts positioning repeatability and surface finish quality. The Fadal NSK Ballscrew Assembly (BLS-0137N-ASS) is the OEM-grade solution for restoring ±0.0005" precision to your 4020 machine's X-axis.

This comprehensive guide covers:

- Why NSK ballscrews outperform generic replacements

- Step-by-step installation best practices

- Maintenance advantages of non-coolant-thru design

- Troubleshooting common wear symptoms

- Why ITSCNC guarantees worry-free procurement

Why the BLS-0137N-ASS Matters for X-Axis Performance

Precision-ground screws (Grade C3 backlash tolerance)

Matched nut assemblies for minimal preload loss

Hardened steel construction (50% longer life vs. aftermarket)

2. Optimized for 4020 Machines

4020" travel length (perfect for standard work envelopes)

Non-coolant-thru design simplifies maintenance

3. Complete Drop-In Assembly

Includes:

Preloaded ballnut

Machined mounting flanges

Thrust bearings

Couplers

No need to source components separately

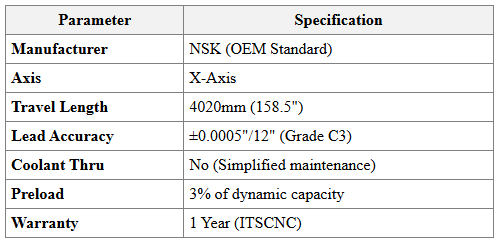

Technical Specifications

Signs You Need Ballscrew Replacement

Critical Symptoms

Backlash exceeding 0.001" (check with dial indicator)

Visible pitting/wear on screw flanks

Sticking or rough motion during rapid traverses

Positional drift during contouring

Pro Tip:

Test backlash by:

Mounting a dial indicator to the table

Commanding small movements (0.010")

Measuring difference between commanded/actual movement

Installation Guide

1. Pre-Installation Checks

Clean ways and remove debris

Verify servo tuning parameters (critical for new screws)

2. Mounting Procedure

Secure thrust bearings (torque to 18 ft-lbs)

Align coupling within 0.001" TIR

Preload adjustment (per NSK specs)

3. Post-Installation

Lubricate with ISO 68 way oil

Run test cuts to verify accuracy

Maintenance Advantages of Non-Coolant-Thru Design

No clogged coolant passages to clean

Reduced corrosion risk in humid environments

Easier lubrication (grease fittings accessible)

Note: Requires manual lubrication every 500 hours

Why Choose ITSCNC?

Genuine NSK Assemblies – No Chinese knockoffs

1-Year Warranty – Coverage for defects

Expert Support – Installation guidance included

Fast Shipping – Most orders ship in 24hrs

FAQ

Q: Can I convert to coolant-thru later?

A: No – This is a sealed assembly. For coolant-thru, order BLS-0137C-ASS.

Q: My Y-axis screw is worn too—do you offer kits?

A: Yes! Ask about our X/Y matched set discounts.

Q: What lubrication is best?

A: Use NSK LG-72 grease or ISO 68 way oil.

Final Recommendation

Don’t let worn ballscrews cost you tolerances. The BLS-0137N-ASS delivers:

NSK precision out of the box

Simplified maintenance

1-year protection

Order today: Fadal NSK Ballscrew Assembly, X-Axis, 4020 Inch, Non Coolant Thru BLS-0137N-ASS

Need installation help? Call our CNC techs: 1-800-342-3475

Comments